Oh, you thought you could just slap on a free-flow exhaust and ride off into the horsepower sunset? Think again. The engine isn’t just a lump of metal with fire inside — it’s a finely tuned symphony of sensors, fuel, timing, and pressure. Change one instrument, and the whole orchestra can fall out of tune. Read ahead to find out how air-fuel ratios, ECU logic, and exhaust dynamics all play their part in keeping your ride smooth, powerful, and sane.

Objectives of an Engine: Achieving the Ideal AFR

At the heart of every internal combustion engine is a simple goal: to convert chemical energy in fuel into mechanical energy through controlled explosions. To do this efficiently, the engine must precisely balance air and fuel — known as the Air-Fuel Ratio (AFR). This balance governs power output, fuel efficiency, emissions, and engine longevity.

That magic happens only when the air and fuel are in the right mix. Too lean, and it knocks, overheats, and can literally melt things. Too rich, and it drinks fuel like there’s no tomorrow, clogs up the exhaust, and power drops. So getting the AFR (Air-Fuel Ratio) just right is what keeps the engine happy.

The stoichiometric AFR for gasoline is 14.7:1, meaning 14.7 parts of air to 1 part of fuel (by mass). Deviations from this value are intentional and situational — leaner for economy, richer for power or cooling.

But what does even Lean and Rich engine conditions even mean?

- Lean (AFR > 14.7:1) = More air, less fuel

→ Better economy, but runs hotter. Can knock or cause damage under load. - Rich (AFR < 14.7:1) = More fuel, less air

→ Cooler combustion and more power, but fuel economy suffers. Also more emissions.

Your ECU’s constantly juggling between the two based on what you’re doing with the throttle.

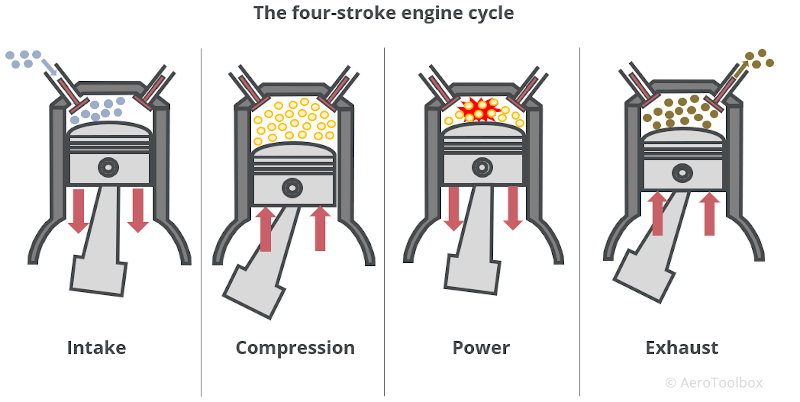

A quick racap on what happens when in a typical four stroke engine:

| Stroke | Crank Angle | Intake Valve | Exhaust Valve | Ignition | Fuel Injection |

| Intake | 0° – 180° | Opens ~10–20° BTDC | Closed ~10–20° ATDC | Off | Starts early in intake |

| Compression | 180° – 360° | Closed | Closed | Fires ~25–35° BTDC | Ends before ignition |

| Power | 360° – 540° | Closed | Closed | Burn happens | No injection |

| Exhaust | 540° – 720° | Closed → Opens ~40° BBDC | Opens → Closes ~10° ATDC | Off | No injection |

That little moment where both intake and exhaust valves are open? It’s called valve overlap. Sounds sketchy, but it helps suck out exhaust gases and pull fresh air in — if everything’s timed right. This small thing has huge ramifications when you change the exhaust, especially because back pressure plays a key role in how effective that scavenging process is. More on this in moment…

Let’s talk about Engine Inputs & Outputs: Basically to ECU

The ECU is like your bike’s brain, trying to make sense of the world through a bunch of sensors and firing orders.

Inputs: What the ECU Reads

- Throttle position: How hard you’re twisting the throttle — tells the ECU how much power you’re asking for.

- Crank & cam position: Tracks engine rotation so spark and fuel happen at the right moment.

- Intake manifold pressure (MAP): Measures air pressure in the intake to estimate how much air is going in.

- Air temp: Colder air = denser = more oxygen. ECU adjusts fuel accordingly.

- Engine coolant temp: Helps with warm-up enrichment and prevents overheating.

- Oxygen sensor: Reads leftover oxygen in exhaust to fine-tune fuel delivery.

- Knock sensor: Detects pinging or detonation. ECU will pull timing to save the engine.

- Gear position / RPM: For load calculation, traction control, and fueling strategies.

- Battery voltage: Ensures there’s enough juice for injectors and ignition.

Outputs: What the ECU Controls

- Fuel injector pulse: How much fuel gets sprayed in.

- Spark timing: When to fire the spark plug.

- Idle control: Keeps the engine stable when you’re off-throttle.

- Exhaust valve / secondary systems: Opens or closes valves to optimize flow or reduce noise.

Basically, the ECU is playing chess at 10,000 RPM.

⚠️ Note: The exact set of inputs and outputs can vary depending on the engine design and manufacturer. Not every system uses all of these sensors or controls — it depends on how the engine is built and what it’s designed to do.

The Exhaust: More Than Just a Noise Maker

Your exhaust isn’t just there to make your bike sound mean. It plays a huge role in how well your engine breathes. Think of it like lungs — Restrictive pipes mean your engine’s holding its breath, while large or free-flow pipes mean it might exhale too quickly — losing the exhaust pulse timing needed for proper scavenging and low-end torque.

Key components:

- Headers: Length and shape control how pressure waves behave. Shorter = high RPM gains. Longer = more low-end torque.

- Collector/Mid-pipe: Where things merge. Good design helps scavenging.

- Catalytic converter: Kills emissions but also adds back pressure.

- Muffler: Controls noise and some pressure tuning.

- Exhaust valve: Opens/closes based on RPM to optimize torque.

That scavenging effect? It’s real. When tuned right, the exhaust leaving one cylinder helps pull fresh air into another during valve overlap. As gases rush out during the exhaust stroke, they create low-pressure pulses that can help draw in fresh mixture during valve overlap — this is called scavenging. But this effect is sensitive: too much or too little back pressure disrupts the timing and efficiency.

Key Points on Exhaust Back Pressure:

- Definition:

- Back pressure is the pressure in the exhaust system that resists the flow of exhaust gases being expelled from the engine. It occurs due to restrictions in the exhaust pathway, such as bends, narrow sections, and mufflers.

- Effects on Scavenging:

- High Back Pressure: If the back pressure is too high, it can hinder the efficient removal of exhaust gases from the cylinder, leading to incomplete scavenging. This means some exhaust gases may remain in the cylinder, diluting the incoming air-fuel mixture during the intake stroke.

- Optimal Back Pressure: A certain level of back pressure is necessary for proper scavenging. It helps maintain a pressure differential that allows for effective exhaust gas expulsion while ensuring that fresh air-fuel mixture enters the cylinder.

- Relation to Valve Timing:

- During valve overlap, having an appropriate exhaust back pressure helps ensure that the exhaust gases exit effectively through the open exhaust valve while allowing fresh air-fuel mixture to enter from the intake valve.

- If back pressure is too low, it may disrupt the flow dynamics, affecting the performance of the engine.

- Impact on Engine Performance:

- Excessive Back Pressure: Can reduce engine power, efficiency, and responsiveness, as it increases the effort needed to expel exhaust gases.

- Properly Tuned Exhaust System: A well-designed exhaust system minimizes back pressure while still providing enough resistance to aid in effective scavenging.

What Happens When You Modify the Exhaust?

When you install a free-flow muffler or a full system, airflow increases — but your ECU is blind to the change unless it’s tuned to know otherwise.

How ECU reacts (Or Doesn’t):

- It continues to use stock fuel and ignition maps.

- It assumes airflow hasn’t changed — this affects AFR.

- O2 sensor (in closed-loop) tries to correct the mixture, but only within limits.

- In open-loop (high RPM/load), the ECU can’t adjust — you may run lean, risking performance loss or engine damage.

- Ignition timing stays fixed, even though faster-burning lean mixtures or different scavenging may need new timing.

Your O2 sensor might adjust a bit, but mostly in closed-loop (low throttle). Once you open it up — you’re running on base maps. If your bike thinks there’s X amount of air and injects Y fuel, but your new exhaust changed everything — you’re now off the map.

That can mean:

- Running lean = hotter, maybe knock

- Running rich = boggy, lower power

- Flat spots or surging

- Fouled plugs or error codes

And the deeper your mod (like full system + decat + air filter), the worse it gets without a tune.

Why the ECU Gets Confused

The ECU works on expectations. It sees air coming in, adds fuel, fires spark. But if you change the breathing (like a new pipe or filter), what actually happens in the chamber isn’t what the ECU thinks is happening.

Unless you reprogram it (via remap, piggyback, or full standalone), it’s still living in the old world.

So:

- AFR goes off

- Timing might be too advanced or retarded

- Engine doesn’t feel right

- You end up chasing problems that tuning could’ve solved in one go

- Fuel economy takes a hit — either too rich or too lean, both waste fuel in different ways

This is where a custom ECU tune or piggyback system becomes essential — to remap fuel injection, adjust spark timing, and make the most of your hardware changes without damaging the engine.

Conclusion: Respect the Balance

Modern engines are engineering marvels — thousands of calculations per second to keep every explosion as perfect as possible. But when you tweak one part — like adding a slip-on exhaust or changing intake flow — you’re disrupting that balance.

That doesn’t mean you shouldn’t mod — it means you should mod smart:

- Want sound? A slip-on is usually safe.

- Want power? You need a full strategy: intake, exhaust, tuning.

- Want the best ride? Tune it. Don’t guess.

Engines are sensitive systems. Get the balance right, and they’ll reward you with power, throttle response, and longevity.

Build smart. Ride hard. And don’t let the ECU do all the thinking for you.

This initiative is led by superbiker Suraj Naik, a passionate enthusiast of biking and DIY mechanics. If you’re as passionate about bikes, performance, and DIY tuning as I am, let’s stay connected!

I regularly share tuning insights, behind-the-scenes workshop work, and real talk about superbike life. Join the community and let’s keep the wrenching spirit alive. Check out my website https://bikersworkshop.com/ and join me on WhatsApp community and my social media channels by clicking on following links.